+86-769-81762582

+86-769-81762582

+86-769-81762582

+86-769-81762582

Our company is mainly used for Ultra- precision mold parts "surface grinding", workpiece shape finishing and surface parllelism and finish Finishing processing. In plane grinding, some special clamp fixtures are used to form part of the grinding. According to material characteristics, dry wet separation. With many years of experience, the grinding master has achieved the high precision machining requirements of every product. That is, the quality of a small number of products, short shipment requirements can also be corresponding.

Our company's wire cutting processing department is equipped with wire culting machine for.

Japanese Western motor.The diameter of the copper wire can be 0.1, 0.15, and 0.2. According to the processing purposes, it can meet different needs.

Japanese AMADA GLS8OPL optical curve grinder which is most suitable for the processing of die parts is introduced, which enables us to meet the processing requirements of high precision and high finish such as punch, concave die, bending forging parts and punch needle.

Our company's oil- based wire cutting processing department is equippde with wire cutting machine for Japanese Sodick

The diameter of the copper wire can be 0.03,0.05,0.07 ,and 0.10. According to the processing purposes,it can meet different needs.

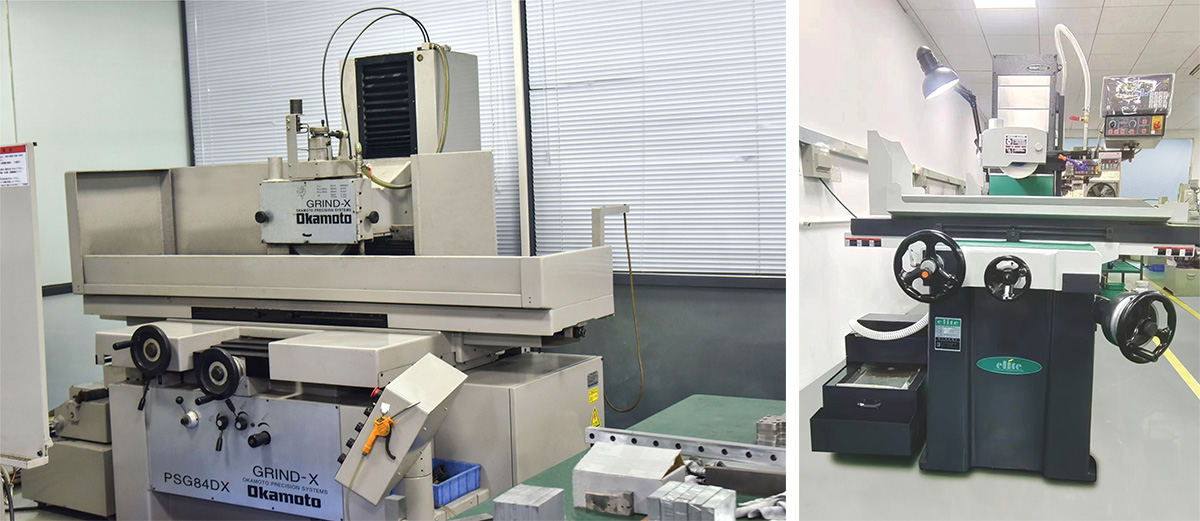

Our company's Surface Grinder processing department is equippde with grinder machine for Japanese Okamoto.

The effective stroke of processing is 800* 400* 300mm,and the plane accuracy is 0.002mm.

Relying on the solid mold foundation, the introduction of advanced testing equipment, fully implement the ISO 9001:2015 quality management system requirements to ensure the quality of each component requirements.

The main precision testing equipment includes projector, tool microscope, altimeter, comparison tester, etc.